As a treatment, speedy cooling of the Zry ingot throughout fabrication (known as beta quenching) produces a much finer intermetallic precipitate inhabitants. This distribution of the transition metals maintains the power of the Zry however improves its corrosion resistance, probably by short-circuiting charge-transport paths between the scale floor and the metallic–oxide interface. In order to get rid of waterside corrosion of cladding as a life-limiting process, modified Zircaloys have been developed. Under PWR water conditions, lowering the tin content material of Zry to 1% and including a comparable focus of niobium produces an alloy with a corrosion rate a number of occasions lower than that of the standard Zry. Modified low-tin alloys can be used either as a whole substitute for the Zry tube wall or as a skinny outer skin on commonplace Zry substrate tubing.

This method is adopted for zircaloy-clad fuels from energy reactors and stainless steel-clad quick reactor fuels. Like the cladding , beneath the effect of neutron flux the hexagonal wrapper tube undergoes change. Geometrical changes, induced by swelling and irradiation creep (underneath the effect of dynamic sodium pressure), concern size, across-flat dimension, and, for subassemblies placed within the periphery of the core, bowing (differential swelling induced by differential flux and temperature between opposite faces of the wrapper tube).

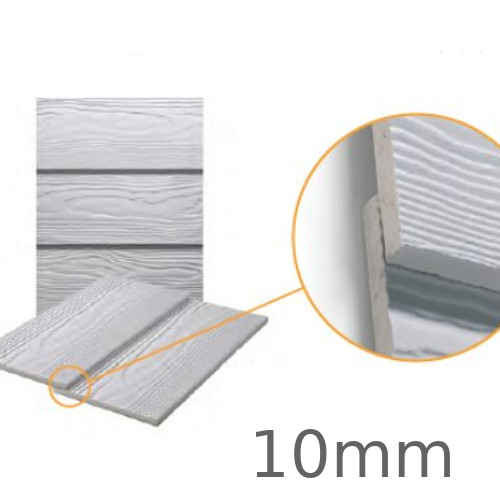

With it, we course of individual parts as well as sequence components, inside as well as outer contours, new and used elements. Cladding in construction is materials applied over one other to provide a pores and skin or layer and used to provide a degree of thermal insulation and climate resistance, and to enhance the appearance of buildings. Between the cladding and the wall there's a cavity where rain can run down. Laser cladding with the aid of energy-based or wire-formed filler supplies can be used for restore work, the appliance of wear and corrosion safety and the production of 3D elements (additive manufacturing).

The ensuing cladding layer was nicely bonded, and the blades exhibited improved fatigue characteristics compared with blades formed by the conventional silver brazing course of. laser beam. The alloy was overlaid on the metal as a powder layer 2.5 mm thick. After melting and bonding by the laser, the alloy layer was 1.5 mm thick and had little or no dilution from the metal. The resulting floor had wonderful wear resistance.

The thickness of the cladding is a design parameter dictated by conflicting performance requirements. The impact of loss of metallic by inside or outer corrosion is less essential for thick cladding than for thin-walled tubing.

The filler material can either be provided in powder form e.g. as metal powder, or with a welding wire. When laser cladding is carried out utilizing powder, the laser usually heats the workpiece with a defocussed laser beam and melts it locally. At the identical time, an inert fuel combined with a fantastic metallic powder is launched. The metal powder melts on the heated area and is fused to the surface of the workpiece.

The constants a and b are basic properties of the material and may be determined from commonplace laboratory experiments on contemporary gas. In explosive welding, a compression drive created by detonation of explosives is used to join overlapping metallic sheets. The joining components are arranged towards one another at an angle of 1–15°, relying on the fabric and methodology, and are prepared with a layer of explosive on the highest. After ignition the becoming a member of areas are moved against each other at high velocity.

Long-time period, in-reactor, oxidation, and hydrogen choose up conduct of zircaloy-2 and Zr-2.5Â Nb pressure tubes, displaying parabolic after which accelerated linear oxidation and hydrogen pickup kinetics in zircaloy-2. A low and uniform fee of corrosion and hydrogen choose up is seen in the in Zr-2.5Â Nb alloy. Differential swelling between cladding, wrapper tube, and spacing system (spacer wire or grids) can induce additional stresses and deformations on these elements and/or generate coolant move perturbations within the bundle. These phenomena have been studied and have notably proven that wires or grid supplies have to be chosen and specified to be able to decrease differential swelling.

2 Cladding

The Building Research Establishment (BRE) has been commissioned to undertake this challenge. This programme is on-going and tests are expected to conclude in the summertime.

Once the pellet/clad gap is closed, any change in pellet dimensions causes stress in the cladding and the synergy between the stress and the corroding medium induces the SCC course of. In order to forestall or reduce pellet/clad interactions, each mechanical and chemical, a coating of graphite powder is utilized on the internal surface of cladding tubes.

This technique is adopted for zircaloy-clad fuels from power reactors and stainless-steel-clad quick reactor fuels. Like the cladding , under the impact of neutron flux the hexagonal wrapper tube undergoes change. Geometrical modifications, induced by swelling and irradiation creep (underneath the effect of dynamic sodium strain), concern length, across-flat dimension, and, for subassemblies positioned in the periphery of the core, bowing (differential swelling induced by differential flux and temperature between opposite faces of the wrapper tube).

With it, we process particular person elements in addition to collection elements, inside as well as outer contours, new and used components. Cladding in construction is materials utilized over another to provide a pores and skin or layer and used to offer a level of thermal insulation and weather resistance, and to improve the appearance of buildings. Between the cladding and the wall there's a cavity the place rain can run down. Laser cladding with the aid of energy-primarily based or wire-formed filler supplies can be used for repair work, the applying of wear and tear and corrosion safety and the manufacturing of 3D parts (additive manufacturing).

Cladding tools is usually designed to go well with a specific product or a bunch of products; this particularly applies to the items required for uncoiling of the strip and the feeding tool. The materials and floor of the rolls in addition to their geometrical shape (cylindrical or topped) are very important.

Depending on the supplies to be bonded, cleaning and roughening are finest carried out by brushing, grinding, or scraping using a specially designed cutter with needles. A suction removal unit is used to evacuate fastidiously any material waste so as to keep away from bonding flaws as a result of poor adhesion. Laser cladding allows us to apply steel layers for wear and corrosion safety with great precision. In addition, it can be used to repair and modify components.

Cladding permits the bulk of the half to be made with inexpensive materials, while offering the floor with desirable properties related to the costlier cladding material. Laser cladding has resulted in surfaces with very good finish, good homogeneity, and really low porosity. Common supplies used for cladding include carbides, iron-primarily based alloys, nickel base alloys, and cobalt base alloys. Laser cladding is a process by which a metal coating is applied onto the floor of a part using a laser as the heat supply.

sheet steel see this page cladding n —

In one, a second inner-surface liner of odd Zry is extruded on the sponge zirconium liner to be able to restore corrosion resistance. In different modifications, the sponge zirconium is alloyed with iron or tin to improve oxidation resistance without affecting the softness that gives immunity from PCI. Standard Zry is sufficiently onerous to be susceptible to emphasize-corrosion cracking (SCC) when the pellet–cladding hole closes and the swelling fuel generates substantial tensile hoop stresses in the cladding. In the presence of an aggressive fission product (iodine is most often cited), a brittle crack can be initiated and penetrate the cladding wall.

The ensuing cladding layer was well bonded, and the blades exhibited improved fatigue characteristics in contrast with blades formed by the conventional silver brazing process. laser beam. The alloy was overlaid on the metal as a powder layer 2.5 mm thick. After melting and bonding by the laser, the alloy layer was 1.5 mm thick and had very little dilution from the metal. The ensuing surface had excellent put on resistance.

Today, Zircaloy-2 and Zircaloy-four are widely used. Phase transformation of Zirconia is, nevertheless, of nice concern.

In PWRs the closure of the gap between the pellet and the clad takes about one full power yr whereas the hole is maintained for a longer period in BWRs. Due to the collapsible clad design of PHWRs, contact between the pellet and the clad is established right from the beginning of the life of the gasoline element. Laser coating or laser cladding can be utilized to regionally functionalize metallic components. In this course of, an edge layer of sometimes zero.1 to 2 mm is utilized to the part. The coating material employed is both powder or wire, or applied prematurely as a tape.

Enhance the curb enchantment of your home with B&Q cladding. All of our timber is responsibly sourced forest friendly timber.

The soften layer is kind of skinny; for instance, when cladding an aluminum alloy it's about zero.5–4μm (Kreye 1985, 1997 ). The dilution of the molten zones leads to plane or corrugated interfaces. During mechanical decladding, the gasoline assemblies are chopped and the gasoline core is leached with nitric acid, leaving behind the undissolved cladding materials for disposal as a stable waste.

Depending on the supplies to be bonded, cleansing and roughening are finest accomplished by brushing, grinding, or scraping using a specifically designed cutter with needles. A suction removing unit is used to evacuate carefully any materials waste in order to keep away from bonding flaws because of poor adhesion. Laser cladding permits us to apply steel layers for put on and corrosion safety with nice precision. In addition, it can be used to repair and modify elements.

The transition metals iron and chromium appear in the microstructure as precipitates of the intermetallic compounds Zr 2 (Ni,Fe) and Zr(Cr,Fe) 2 . These minor alloying parts enhance corrosion resistance to an extent dependent on the scale of the precipitates. Laser cladding has been applied to hardening of steam generator turbine blades and reached pilot production standing [four ]. The blades had a machined pocket, into which powdered cobalt-based mostly metallic (Stellite 6) was fed ahead of the laser beam.

PRODUCTS

Hydrogen addition in boiling water situations just isn't very efficient because of the segregation of hydrogen within the steam phase. The interplay that gasoline cladding tubes expertise due to the fission merchandise on the internal floor is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are a few of the fission merchandise which contribute strongly to the SCC course of. Due to the combined effects of thermal enlargement of gasoline pellets, gasoline swelling as a result of fission gas release, and the coolant pressure on the outer surface of gas tubes, cladding tubes collapse on the fuel pellets.

is produced and the danger of a massive secondary hydriding failure is increased. In response to this unforeseen consequence, a number of fixes were introduced.

The complete melting of the filler leads to a dense layer with optimal adhesion to the substrate. The most typical software is for the wear protection, e.g. of tools, but additionally corrosion safety or excessive temperature resistance can be specifically improved. Common onerous alloys primarily based on cobalt, nickel and iron are used with and with out the addition of hard materials. But additionally specifically adapted supplies may be applied.

The graphite layer offers lubrication to minimize the mechanical interactions, and acts as a barrier against the migration of dangerous species to confused areas of fuel tubes. The authentic function of tin in Zry was to mitigate the lack of corrosion resistance brought on by pickup of impurity nitrogen during fabrication of the alloy.

Enhance the curb enchantment of your house with B&Q cladding. All of our timber is responsibly sourced forest friendly timber.